To speak of the history of sherry wine is also to speak of the legacy of coopers in Jerez and their time-honored craft. These skilled artisans, known as “toneleros”, are responsible for the meticulous process of sherry cask construction, ensuring each barrel is expertly built to enhance the aging process that influences part of sherry’s unique character. The barrel makers from Jerez have perfected their cooperage techniques, using only the finest materials and applying long but precise methods of seasoning to prepare the wood for its vital role in the wine maturation. Coopers’ dedication to cask craftsmanship has been instrumental in shaping the exceptional reputation of sherry wines and the region along the time among locals and foreign distillers. Becoming familiar with the concept of artisanal is indispensable to understanding not only the value of the extraordinary skills that are necessary to manufacture what these professionals do, but also to appraise the cognitive load that those [manual] tasks bear with them.

If you are interested in expanding the artisanal legacy of the region, don’t miss the article dedicated to almacenistas.

THE ROLE OF COOPERS IN JEREZ

Coopers in Jerez are more than just barrel makers—they have played a fundamental role in shaping the region’s traditions and culture. While the number of cooperages and artisans has drastically declined compared to the previous century, sherry coopers have recently regained prominence, not only within Jerez but also on a global scale. Today, their casks provide exceptional value to distilleries worldwide, carrying both the tradition and the name of “Jerez” to every continent of the world.

Much like the region’s winemaking history, the origins of cooperages in Jerez are both elusive and well-documented at the same time. The trade flourished alongside advancements in navigation developed by the Phoenicians, Romans, and Greeks, who perfected shipbuilding techniques that were later applied to the crafting of barrels and amphorae for transporting goods across the Mediterranean. As early as the 8th century BC, Herodotus described a maritime trade route between Georgia and Armenia, specifically mentioning the transport of wine barrels. Similarly, Homer referenced the Greek tradition of aging wine in pythai, a practice also noted by Pliny the Elder.

Although the use of wooden barrels for wine transport was well established since ancient times, the official recognition of coopers as a profession did not occur until 1444, when King Charles VII of France approved the statutes of the Cooper’s Guild. It wasn’t until the following century that clear references emerged regarding the use of chestnut and cherry wood barrels—reinforced with wicker or tree bark—for wine aging in the sherry region.

A document from June 1491 mentions a cooper based in Jerez who committed to the “craft of 10 high-quality wooden casks, well-tightened with hazel and chestnut rims.

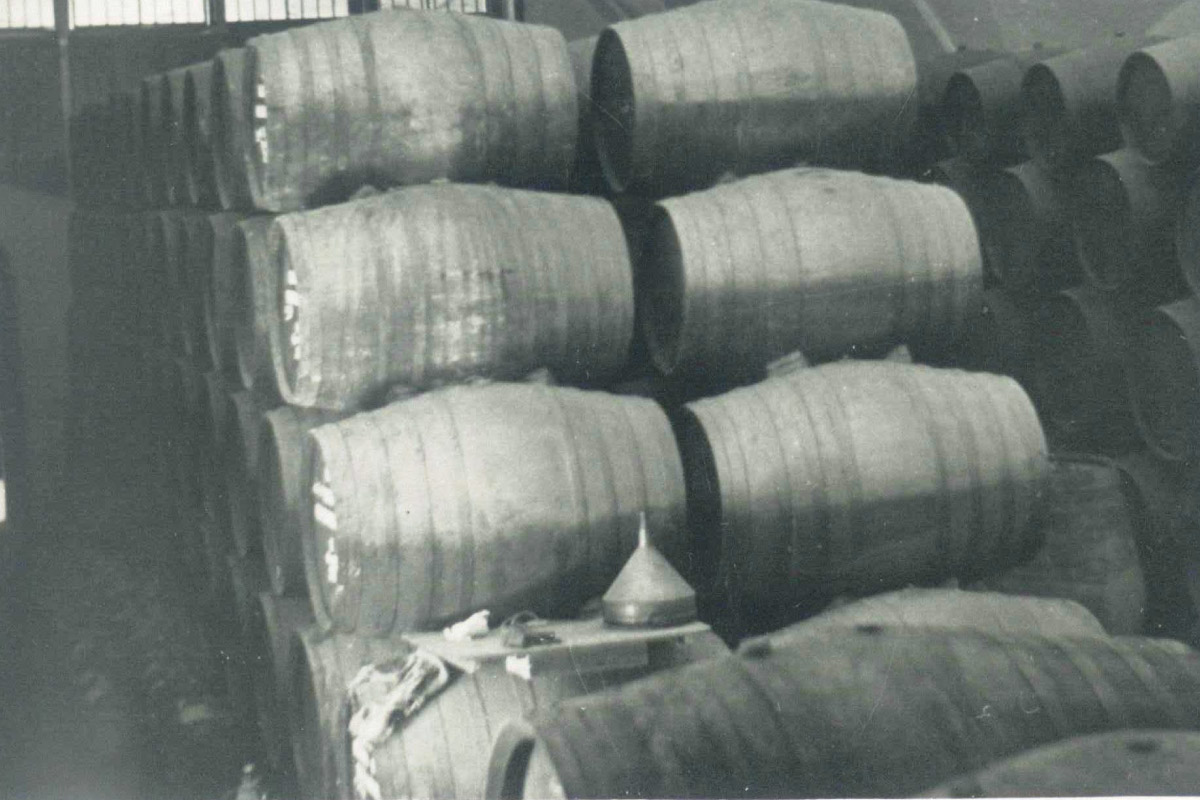

In the 15th century, the “Gremio de tonelería de Jerez” (Coopers’ Guild of Jerez) was established, formalizing practices, materials, barrel sizes, and pricing, while also regulating penalties for mala praxis or the use of inferior wood. It was in the 19th century that sherry coopers’ influence truly flourished, driven by the industrialization of the region’s wine sector. By 1874, Jerez de la Frontera alone housed 30 cooperage workshops, employing over 1,000 artisans who handcrafted around 60,000 sherry casks per year— At an impressive rate of about 1.5 casks per cooper per week.

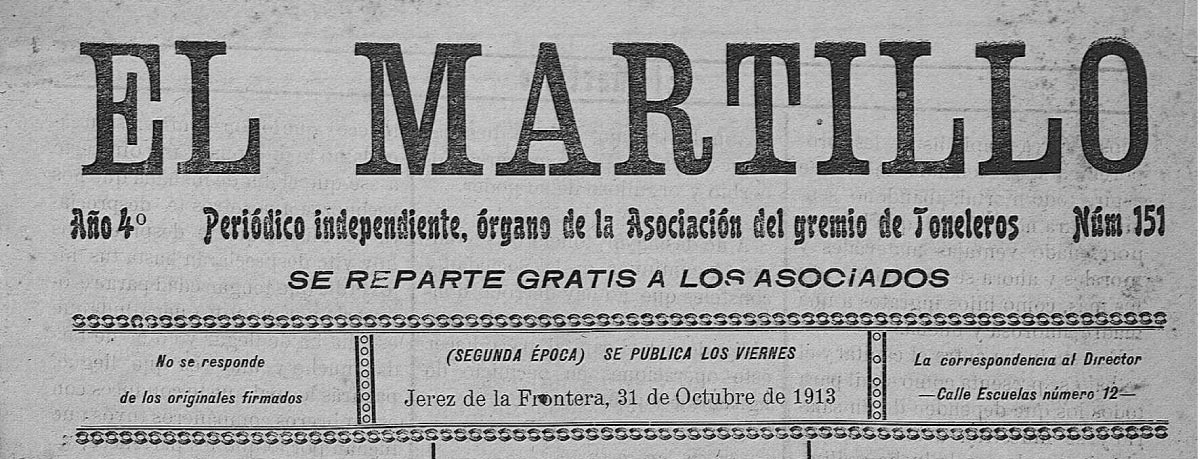

Sherry coopers left a deep cultural imprint on the local society, influencing traditions, language, lifestyles, and philosophies that persist today. Proof of their significance as a community was, for instance, the publication of their own newspaper, “El Martillo”, which was distributed free of charge among members of the guild. This association held progressive ideals for its time, promoting cultural and intellectual exchange by organizing literary gatherings and encouraging members to get educated.

This newspaper was published between 1897 and 1936, disappearing due to the imminent outbreak of the Spanish Civil War.

Language, an integral part of the region’s cultural universe, also found a heavy influence within the cooperage trade. Over 650 specialized terms related to cask craftsmanship have been recorded, with more than 50 referring specifically to tools used in sherry cask construction.

By the early 20th century, the cooperage landscape had changed significantly. The Official Guide of Jerez, published in 1923, listed only 10 remaining cooperage workshops. During this period, wineries began establishing their own in-house barrel workshops (“trabajaderos”) to streamline production and oversee both barrel-making and maintenance. Following the creation of the Jerez–Xérès–Sherry Denomination of Origin in 1935, Jerez coopers ended up gaining national recognition for the outstanding quality of their barrels.

Today, the cooperage industry in the sherry region produces over 100,000 sherry casks annually, combining semi-mechanized production with traditional techniques such as “levantados”, “secados”, “tostados”, and assembling barrels with metal rims. Currently most of these barrels are exported to whiskey-producing countries nowadays, but before leaving the DO geographical zone, they spend at least two years being seasoned with sherry wine. During this period, the wood absorbs approximately 10–15% of the wine, transforming the barrel into the renowned Sherry Cask—a vessel that carries centuries of legacy.

WHY COOPERS ARE ESSENTIAL TO SHERRY PRODUCTION

Coopers were—and still are—generally strong and resilient individuals, capable of enduring the immense physical demands of working with wood, wine and fire. Although these professionals are nowadays assisted by specialized machinery, particularly in cutting the wood, their expertise still plays a fundamental role in maintaining and repairing casks, preserving their integrity, quality and the eventual consistency of the wine.

Beyond their work with barrels, sherry coopers, especially those employed in wineries, have gradually acquired knowledge and skills extending beyond cask maintenance to an understanding of the wine itself. Their know-how allows them to take on a versatile and cross-functional role—not only mastering the complexities of wood but also the nuances of the wine that fills their creations. This dual role provides wineries with invaluable professionals who understand the effects, consequences, techniques, and practices of winemaking in a more holistic way, fostering a synchronized and well-aligned ecosystem within the bodega.

THE ART OF CASK MAKING: A TIMELESS CRAFT

Sherry wineries use various types of barrels, with each influencing the final result and possibly adjusting the wine’s aging pace. Throughout the history and cooperage tradition of the sherry region, numerous barrel formats and sizes have been created and used, along with woods of different origins. This combination of factors has led to a diverse and distinctive range of barrels used in Jerez.

Despite this variety and diversity, the world-renowned Sherry Cask adheres to a set of unique characteristics:

– Made from oak

– 500-liter capacity

– Distinctive rounded shape

– Toasted and then seasoned with sherry wine

TYPES OF BARRELS USED IN SHERRY CRAFTING

The iconic cask is known in the region as “bota jerezana”, with a capacity of 600 liters (158.5 gal). Although its dimensions can vary slightly depending on the cooper, they are usually approximately as follows: 136 cm long (4’, 5.5’’), 102 cm at the widest point (3’, 4’’). This vessel is also known as “bota gorda (fat cask).

Despite the important prominence of this type of cask there are several others used in the region that also play an interesting role to this occupation in the sherry barrel business:

Bota de exportación: or “export cask”, the one used in the past for transporting the wine, has a capacity of 500 litres (132 gal) and is slightly shorter and smaller the bota jerezana.

Bota de recibo: or “receipt cask” was traditionally used in the past for local or indoor transportation and has a capacity of 516 litres (136 gal).

Bota bodeguera: often used in the lower scale of the solera system for its larger capacity and strength or for various internal tasks in the bodega. It has a total capacity of 566 litres (149,5 gal).

Apart from those vessels already mentioned there are others which have been or continue to be used like the “media bota” or half cask of 250 litres (66 gal), the 700 litre (185 gal) “bocoy”, the “cuarta de bota” (quarter cask) and the “octavo” (octave) of 62.5 litres (16.5 gal).

THE IMPORTANCE OF WOOD IN SHERRY CASKS

The exact date when sherry casks began to be made from American oak remains unknown. However, records suggest that this oak primarily came from forests in New Orleans and New York. Given the thriving overseas trade, it is likely that American oak started being used (with that purpose) around the mid-18th century. Before its introduction, sherry coopers crafted barrels from a variety of local woods, including cherry, chestnut, hazel, and holm oak.

Insertar:

At this time, oak is the preferred choice for Sherry cask construction due to its durability, flexibility, and porosity. It allows controlled oxidation and imparts subtle notes of vanilla, spice, and toast to the wine. The majority of oak used in the industry today comes from certified forests in northern Spain (Cantabria and Galicia), the Czech Republic, Romania, and, to a lesser extent, France.

THE WORK OF COOPERS: MAINTAINING THE CASKS

A cooper’s work extends beyond cask construction or repair; it involves ongoing maintenance, repair, and careful monitoring of each barrel. From detecting leaks to reinforcing structural integrity, their daily tasks ensure that the aging process remains consistent and uninterrupted.

Daily Tasks of a Cooper in the Bodega

Inspecting and Repairing Casks

Regular inspections are essential to identify leaks, cracks, or weaknesses in the wood. Coopers meticulously assess each cask, replacing damaged staves, tightening hoops, and ensuring an airtight seal to prevent wine loss and contamination.

Ensuring the Longevity of Sherry Casks

Proper maintenance extends a cask’s lifespan, reducing the need for new barrels while preserving the unique characteristics absorbed by the old wood. By carefully managing the whole cask stock in the cellars, coopers are constantly ensuring quality and consistency for new generations of wine to come for decades.

Key Cooperage Techniques

Salidero: Detecting and Fixing Leaks

Barrels are naturally porous, which can sometimes lead to liquid loss, especially in older barrels. Winery teams regularly inspect casks to detect leaks and prevent wine loss. Small leaks typically seal themselves as glycerin or sugar thickens upon air contact, requiring only monitoring. However, large leaks demand immediate action as they can alter wine levels, attract pests, and foster microbial growth that could harm both the wine and the wood.

Throughout the day, while the Lustau team performs other tasks, they carefully inspect casks for leaks. The dark matte wood helps make wine sheen more visible, aiding in quick detection. Smell is also crucial—significant leaks create a distinctive aroma, allowing experienced workers and coopers to locate and diagnose the issue swiftly. While all team members participate, identifying leaks by scent requires expertise. Coopers, with their deep understanding of wood and casks, are the primary specialists. However, winemakers and warehouse workers also contribute to this essential task.

Detecting leaks prevents wine loss and protects the entire aging system. It also ensures a clean environment, crucial for biologically aged wines, helping preserve the flor yeast layer’s delicate ecosystem and maintaining the sherry’s integrity.

Cierre de Poros: Sealing the Wood

As stated above, casks are naturally porous, and over time, temperature fluctuations and wine maturation can cause their surface to expand and shrink, creating small openings where wine may escape. When a cask undergoes solid maintenance (or is being repaired), one of the first tasks is sealing these pores to ensure it remains as watertight as possible for the longest time. Coopers identify these pores and use a heavy hammer to drive a small conical wooden peg into the affected area. As the peg is inserted, it compresses the surrounding wood fibers, effectively sealing the pore. Once secured, the excess wood is trimmed to blend seamlessly with the cask’s surface. This delicate process requires extensive expertise in wood, making it a task reserved for experienced coopers only. Properly sealed casks not only prevent wine loss but also contribute to efficient cask management, preserving the legacy of the wines maturing within. By maintaining their integrity, these casks continue to impart their character to each new generation of sherry, ensuring quality and consistency in every bottle.

Enea: Using Natural Materials for Repairs

Over time, temperature and humidity fluctuations cause wood to lose flexibility, making it more susceptible to swelling and contraction. This can create small gaps between cask joints that, if left unaddressed, may lead to significant leaks. To prevent this, coopers use “enea”, a natural plant fiber, to seal these joints and maintain the cask’s watertightness. The process is meticulous and time-consuming, requiring the removal of several cask rims while ensuring the bottom remains intact. Once the staves are loosened, a dry enea leaf is carefully inserted into the joint, cut to size, and positioned so it does not come into direct contact with the wine. This traditional technique, free of adhesives or chemicals, relies on Enea’s natural flexibility when moistened, making it a sustainable and effective solution. Only skilled coopers can perform this task, as handling cask rims demands precision and expertise. Properly sealed casks extend their lifespan, reducing the need for new wood while ensuring the optimal conditions for aging wines.

Lavado de Botas: Cleaning and Preparing Casks

Over time, wines leave behind sediments and salts on the cask’s interior, which must be removed before reuse to prevent contamination and unwanted flavor. Washing also serves as a final check to ensure previous repairs have been effective. The process involves placing the cask’s bunghole over a high-pressure washing fixture, which sprays water in a fan shape while the cask rotates on a support stand, thoroughly cleaning its interior. After washing, the cask is inspected for leaks before proceeding to sulfur burning. This task is performed by coopers, and once familiar with the washing apparatus, it becomes a straightforward procedure. Proper cleaning ensures casks remain free of defects, preserving the integrity of aged wines and maintaining the overall wine ecosystem.

Pajuelas: Sterilizing Casks with Sulfur

After washing, casks must be sterilized to eliminate unwanted microorganisms. This is done by igniting sulfur strips inside the cask, producing dense smoke that removes oxygen and neutralizes microbes. The cask is briefly sealed to allow the smoke to permeate the wood. This process is carried out by coopers and experienced winery staff. Proper sterilization helps maintain microbial balance, especially in biologically aged wines, and prevents cross-contamination, ensuring the integrity of the aging process.

THE IMPACT OF COOPERAGE ON SHERRY QUALITY – HOW CASK MAINTENANCE AFFECTS SHERRY AGING

A well-maintained cask allows for a controlled aging process, where oxidation and wood interaction occur harmoniously. Poorly maintained barrels, however, can lead to spoilage or inconsistencies in flavor. The knowledge and skills of sherry coopers ensure that each cask contributes positively to the aging process, resulting in a refined and balanced sherry.

Get to know the sherry effect and how every sherry affects to the barrel wood

THE ROLE OF CASKS IN SHERRY’S UNIQUE FLAVORS

Envinado: The Seasoning Process

The seasoning process, or “envinado”, is the final and defining stage in the creation of a cask. During this phase, the cask takes on its unique identity and exceptional value. This step establishes a nearly symbiotic relationship between the wood and the wine, marked by a delicate balance of interactions.

The wine not only absorbs flavors and aromas from the wood but also actively transforms the cask itself, subtly altering its structure and chemical composition over time. This seasoning will ensure that both the wine and the cask evolve together, creating a vessel capable of imbuing spirits with the distinctive character of sherry wine.

New Sherry Casks and Their Use in Other Spirits

The diversity of sherry wine styles plays a pivotal role in the development of flavors in spirits aged in sherry casks, such as whisky. Sherry’s complex aging processes—ranging from biological aging under “flor” yeast to oxidative aging—soak through the casks wood with distinct compounds that affect how the spirit absorbs flavors and aroma over time. Moreover, sherry casks also contribute to the smoothness and depth of the spirit aged inside, affecting not just flavor, but texture and mouthfeel as well. The unique characteristics of sherry wine make its casks an invaluable tool for distillers and spirit makers seeking to refine and develop the quality of their aged spirits.

With the growing demand for sherry casks in the spirits industry, tailored casks have become increasingly essential. Cask designs are now being adapted to meet the specific needs of distilleries, focusing on elements like size, rim distribution, wood type, and seasoning. This customization ensures optimal amplification in each spirit, adapting the cask to the spirit maturing, aging and finishing particularities at the distillery.

CONCLUSION: THE UNSUNG HEROES OF SHERRY – THE ENDURING LEGACY OF COOPERS IN JEREZ

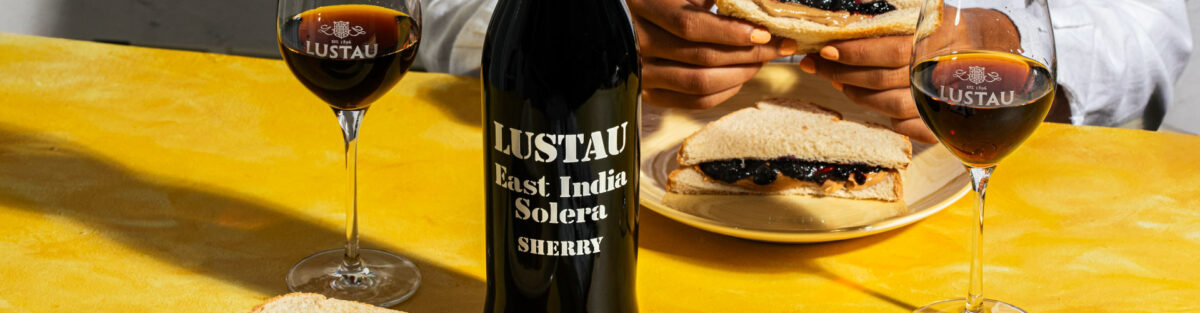

Sherry coopers are the backbone of the industry, ensuring that every cask contributes to the production of world-class wine. Their expertise in sherry cask construction, maintenance, and seasoning techniques is indispensable. The next time you enjoy a glass of sherry, remember the dedication of the barrel makers from Jerez who help bring its diversity in flavors to life.